BRASS

Oxidable metal alloy formed by copper (Cu) and zinc (Zn), historically used for its aptitude to plastic deformation, good mechanical features and excellent tool workability. It is necessary to distinguish between binary brass (CuZn) and ternary brass including a third chemical element necessary to bring specific characteristics to the material. In most cases, this third element is lead (Pb), which is essential to facilitate chip breaking and allow high-speed machining with limited tool wear.

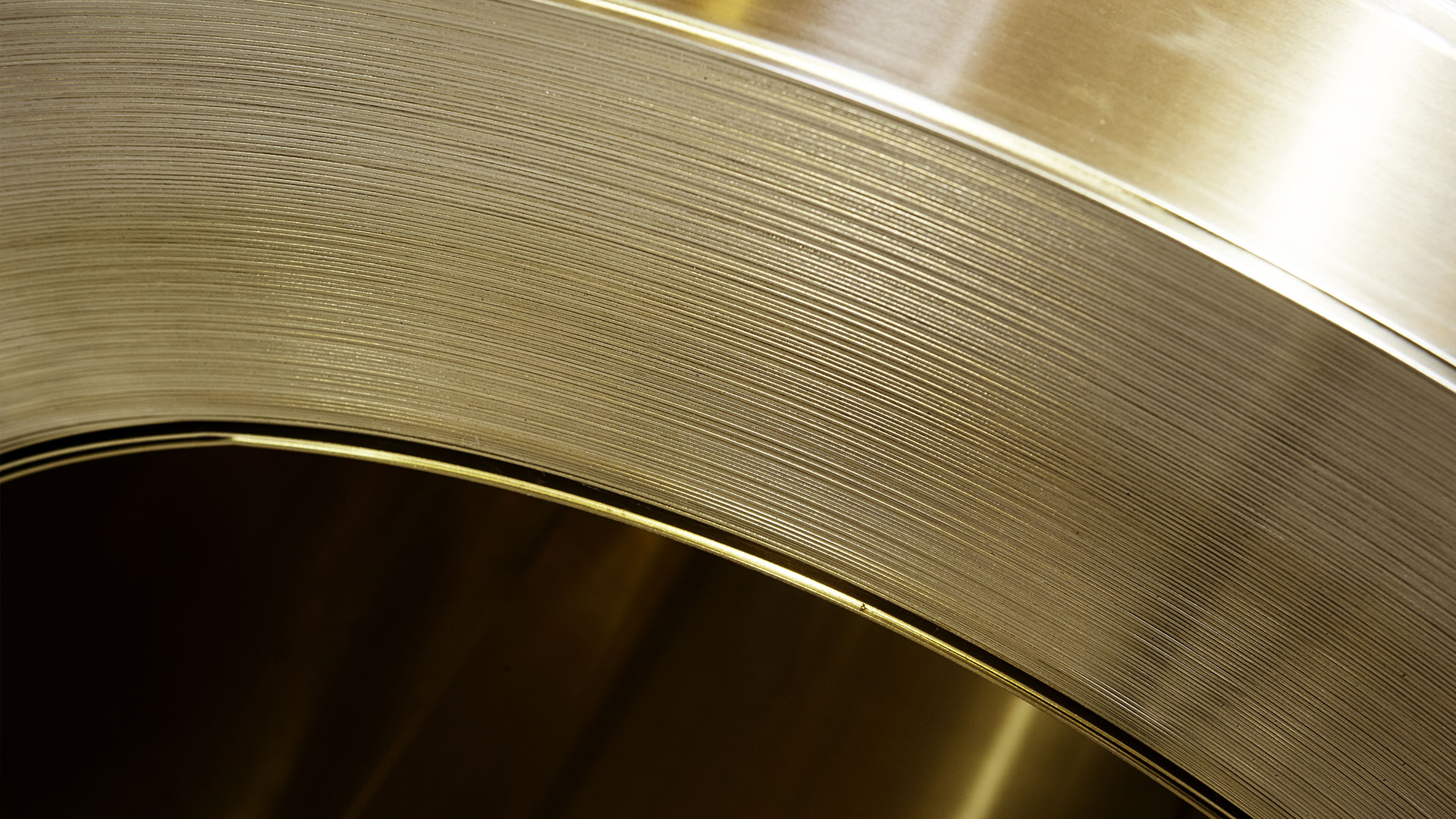

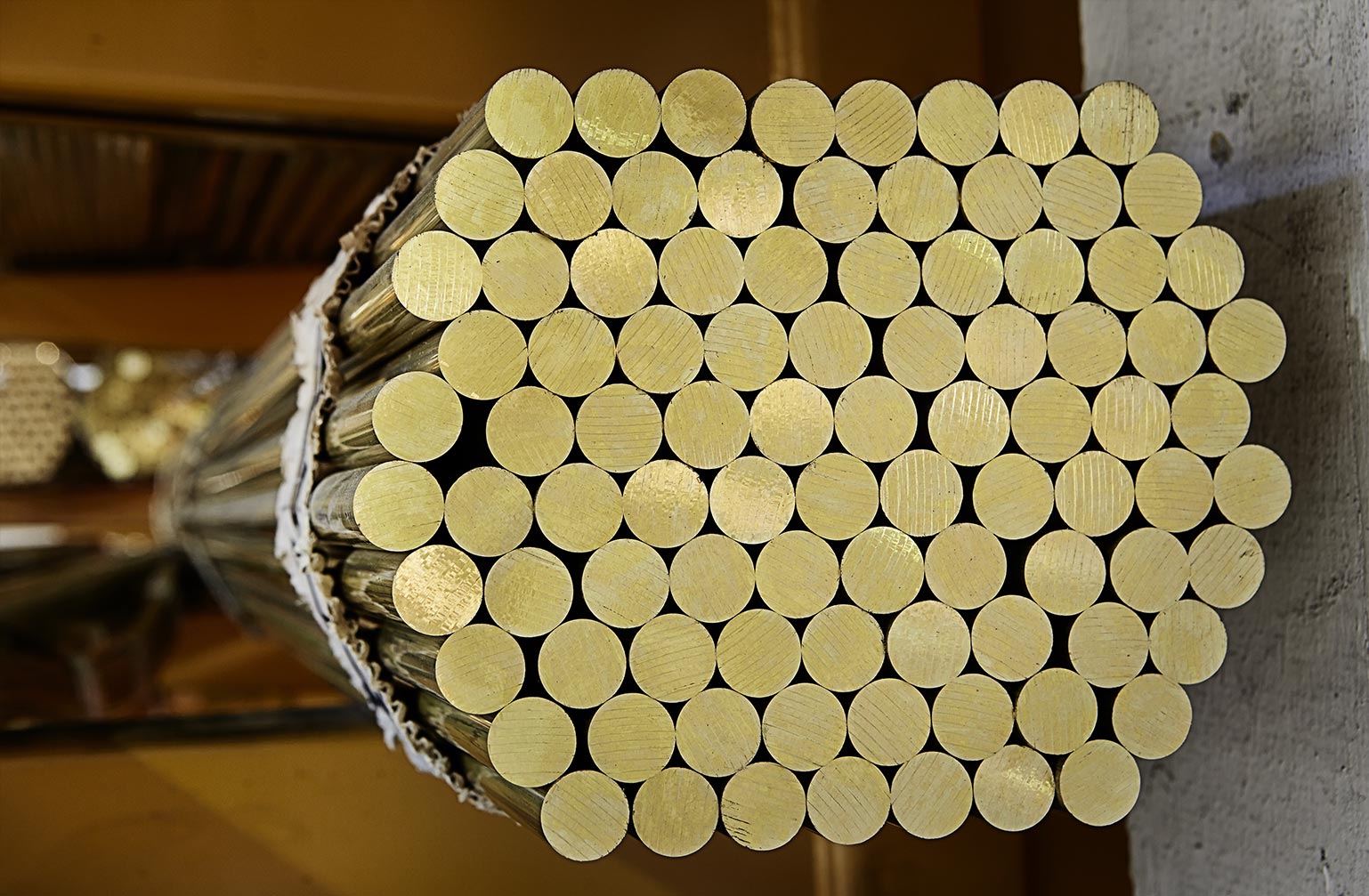

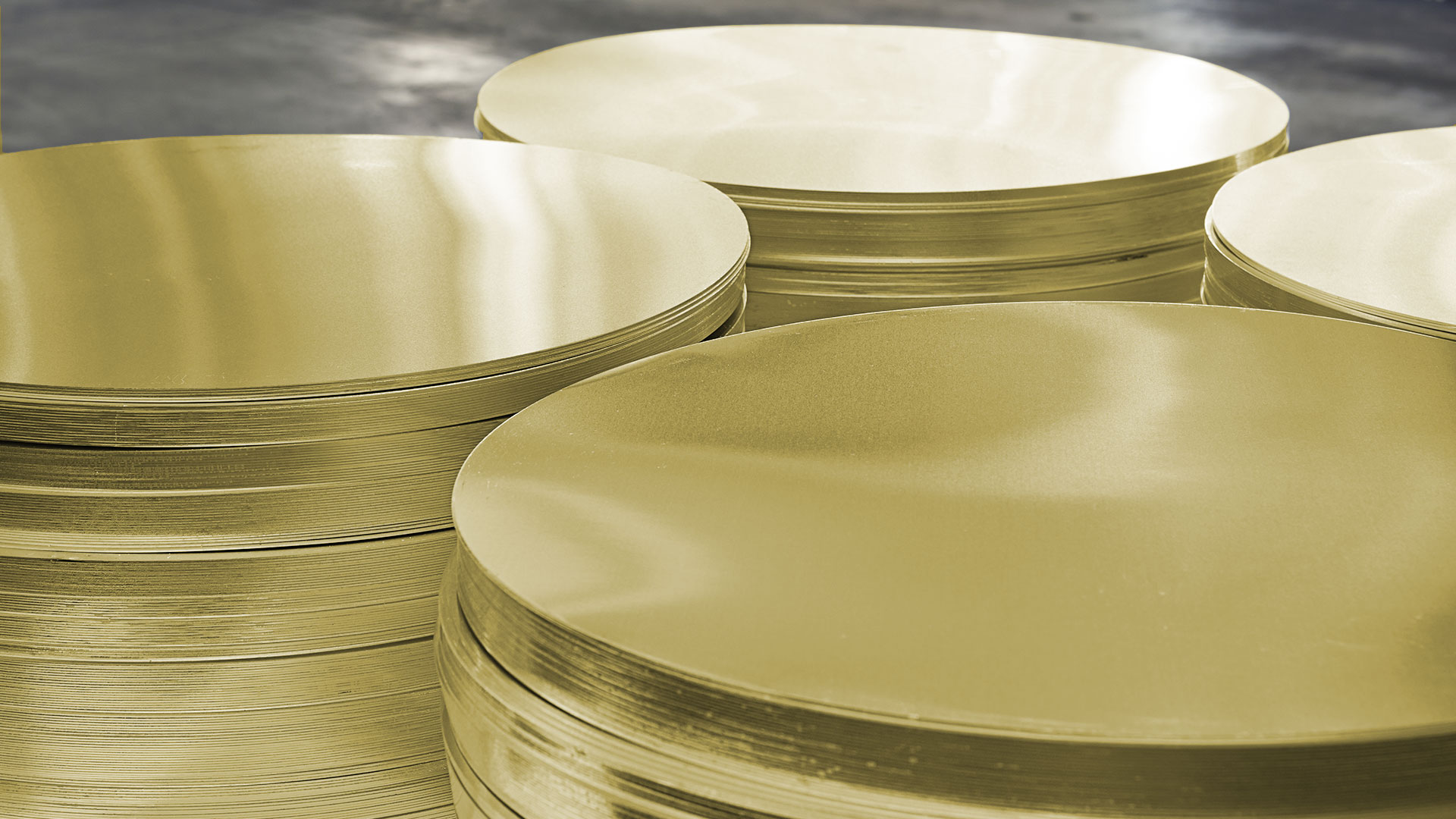

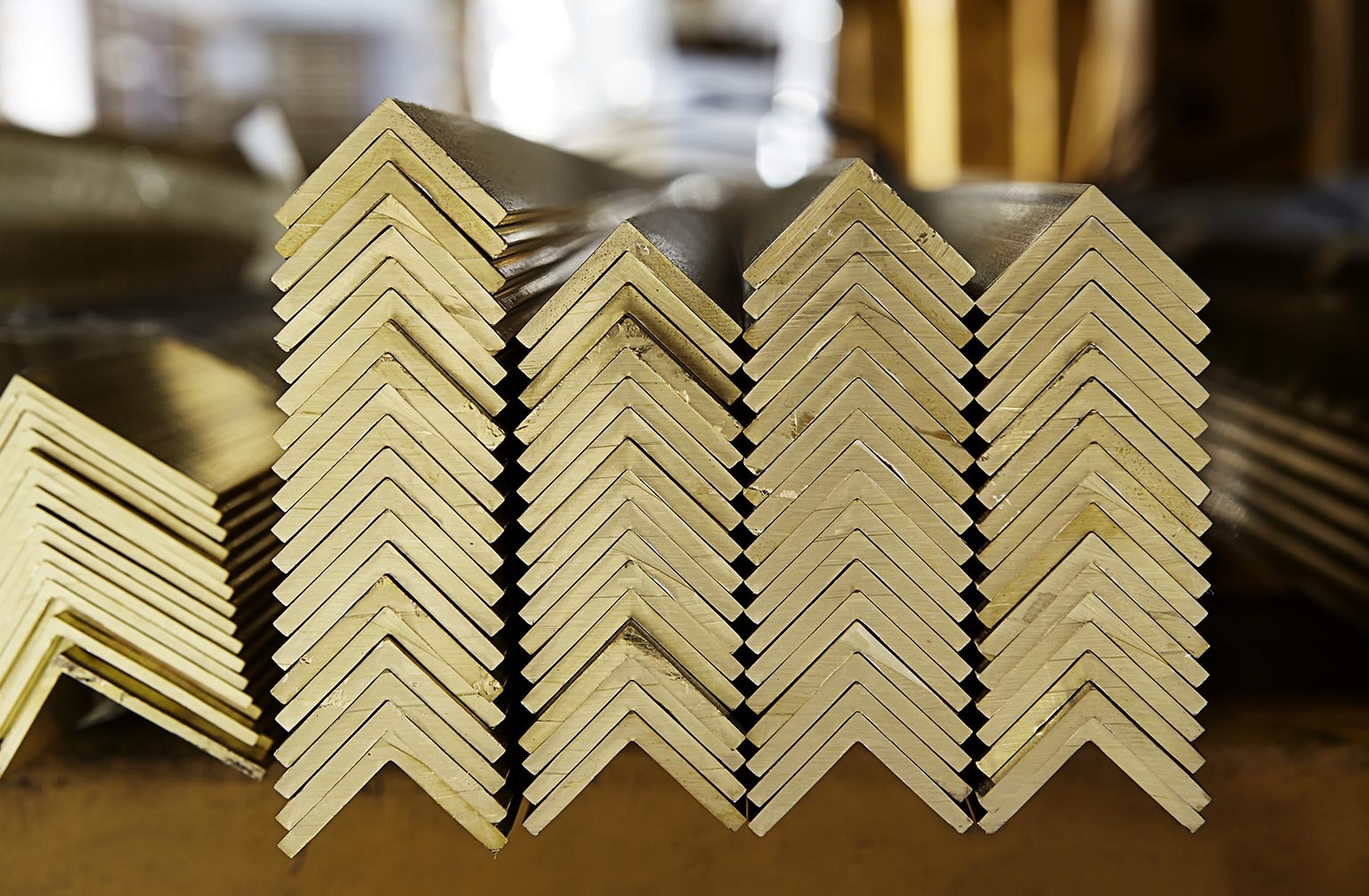

Brass semi-finished products

Our company is able to offer any type of semi-finished product.

Alloys and uses

Our range of alloys for different applications and industrial sectors.

| ALLOYS | PRODUCT | note |

|---|---|---|

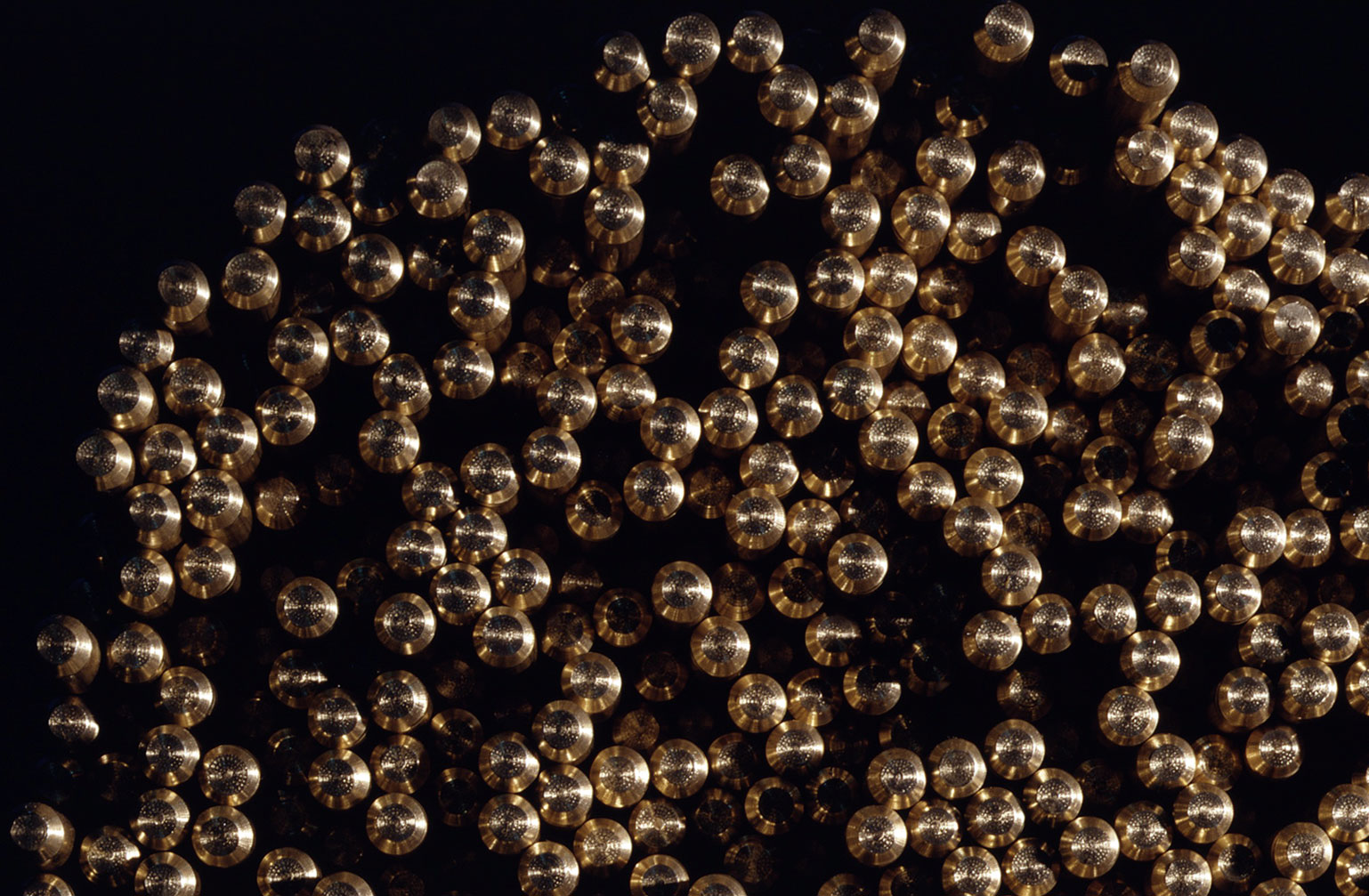

|

CW506L

Cu Zn33 (Ot 67)

|

Brass sheets, Brass strips, Brass circles

|

Alloy used for both cold deformation and mechanical processing. Used for furnishings in general (beds, chandeliers and taps). Replaced by the Ot 63 alloy, having the same drawing index. |

|

CW508L

Cu Zn37 (Ot 63)

|

Brass tubes, Brass sheets, Lead-free wire, Brass strips, Brass circles

|

Alloy used for both cold deformation and mechanical processing. Used for furnishings in general (beds, chandeliers, taps). |

|

CW508L Pb < 80 ppm

CuZn37, CuZn42

|

Brass sheets, Lead-free wire

|

To meet the increasingly restrictive containment rules for elements considered toxic within alloys, we are able to offer semi-finished products with a reduced Pb content (with certification). |

|

CW510L

Cu Zn42

|

Bars in rods

|

It is also called "American alloy" as it is produced specifically for this market and in particular for products intended for contact with drinking water. This alloy, which has a maximum lead content of 0.2%, complies with the strictest laws of the United States but also with European and Italian standards and laws, combining this characteristic with excellent hot workability and a discreet machinability. This alloy, properly worked, is able to brilliantly pass the tests established by the NSF 61 Standard. |

|

CW603N

Cu Zn36 Pb3

|

Bars in rods, Brass tubes

|

Due to its easy cold deformation it is also called "bendable alloy". |

|

CW612N

Cu Zn39 Pb2

|

Hollow bars, Brass sheets

|

Alloy used for the production of mechanical parts where excellent removal of shavings is required (gears for watches, shower heads, plates, engravings and serigraphs). It is also called "watchmaking alloy". |

|

CW614N

Cu Zn39 Pb3

|

Hollow bars, Bars in rods, Bars in coils

|

Alloy used for mechanical processing in general. |

|

CW617N

Cu Zn40 Pb2

|

Hollow bars, Bars in rods, Bars in coils

|

Alloy used for the manufacture of mechanical, electrical and decorative parts. Suitable for both cold deformation and mechanical processing. |

|

CW618N

Cu Zn40 Pb2 Al

|

Bars in rods, Profiles

|

Alloy used in several applications: locks, door knockers, decorations. |

|

CW624N

Cu Zn43 Pb2 Al

|

Profiles

|

Alloy used in several applications: locks, door knockers, decorations. |

|

CW713R

Cu Zn37 Mn3 Al2 Pb Si

|

Bars in rods

|

Thanks to the presence of hard intermetallic compounds finely dispersed in the metal chemical structure, it has excellent mechanical properties and resistance to wear. The good hot deformability combined with the sufficient qualities of workability for chip removal allow it to be used in excellent condition for bearings, bushings and mechanical parts subject to wear. Good resistance to atmospheric agents. |

Can't find the alloy you are looking for?

We can also supply semi-finished products in other alloys, for example pinchbeck, CW602N, CW723R, CW724R etc.

Solutions and services

Mario Crespi S.p.A. is able to offer its customers all types of semi-finished products, as well as various additional services for different needs.

Stock Service

We own one of the largest stocks ready for international delivery for hollow bars and solid bars, also in low lead content alloy.